Repairing power supply faults that disrupt a glass cockpit on a Piper Warrior requires a systematic approach to accurately diagnose and fix the electrical issue. The glass cockpit, whether a Garmin G5 or another system, is highly sensitive to voltage fluctuations, and a fault can cause intermittent failures, display flickering, or a complete shutdown. The problem is rarely with the display unit itself but with a component in the aircraft’s electrical system.

Common Power Supply Faults

The electrical system of a Piper Warrior, like any piston single, must provide a clean and stable power supply. A fault in this system can cause major disruptions to the avionics.

- Unstable Voltage ⚡: This is the most frequent cause. A failing alternator or a faulty voltage regulator can send a voltage that is either too high or too low to the avionics bus. The glass cockpit has a built-in protection circuit that will shut down the unit to prevent damage, causing a display flicker or a crash.

- Poor Ground Connections 🔌: A loose or corroded ground connection is a common culprit for intermittent faults. This can cause voltage spikes or a “floating ground,” leading to erratic behavior.

- Failing Circuit Breakers or Wiring 🧵: A worn-out circuit breaker can trip prematurely, causing a sudden power loss. The wiring harness itself can also be a source of failure if it is chafed or has a loose pin in a connector.

Diagnostic and Repair Workflow

A professional and methodical workflow is critical for resolving these issues. The principle of authority is paramount; all work must be performed by a certified avionics technician trained on the specific systems.

- Pilot Debrief and Symptom Analysis 🗣️: The technician will begin by getting a detailed account from the pilot about the exact symptoms. Did the display flicker after a specific electrical load was turned on? Was the problem intermittent?

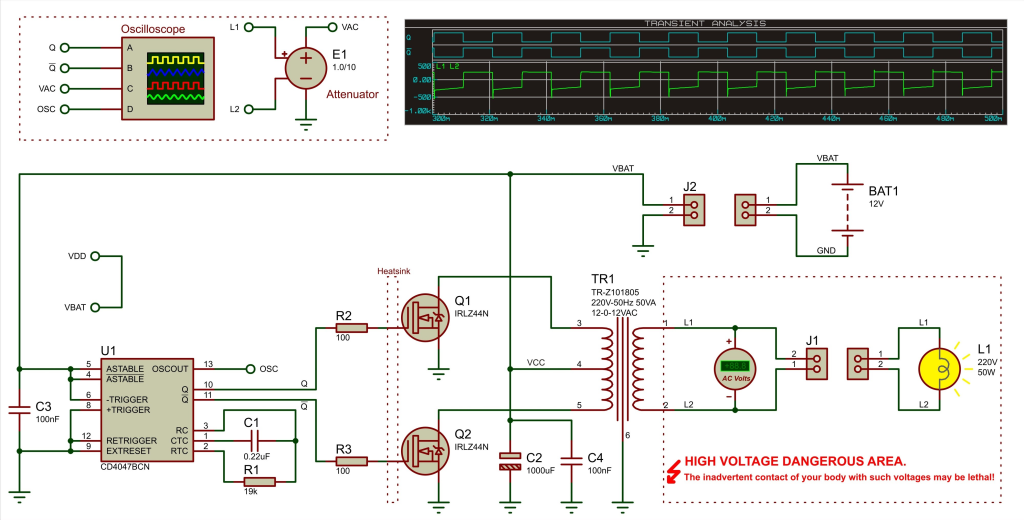

- Electrical System Checks 🛠️: Using a high-quality multimeter and an oscilloscope, the technician will perform a series of checks. They will check the voltage output of the alternator and the main avionics bus under various electrical loads.

The oscilloscope helps detect brief voltage spikes that a multimeter might miss. 3. Wiring and Connector Inspection 🔍: The technician will perform a thorough physical inspection of the avionics bay, paying close attention to the wiring harness and connectors for signs of chafing, corrosion, or loose pins. 4. Repair: Once the problem is isolated, the repair can range from a simple wiring fix to a component replacement. A faulty voltage regulator or alternator will be replaced, a bad ground connection will be cleaned and tightened, and any damaged wiring will be repaired with certified parts.

Our commitment to this professional workflow has built our reputation on social proof from a loyal customer base across California, Arizona, and Nevada. Our unique selling proposition is being the only 24/7 maintenance center in the area. This commitment to consistency means we can begin the diagnostic and repair process immediately, minimizing your aircraft’s downtime and getting you back in the air with confidence.